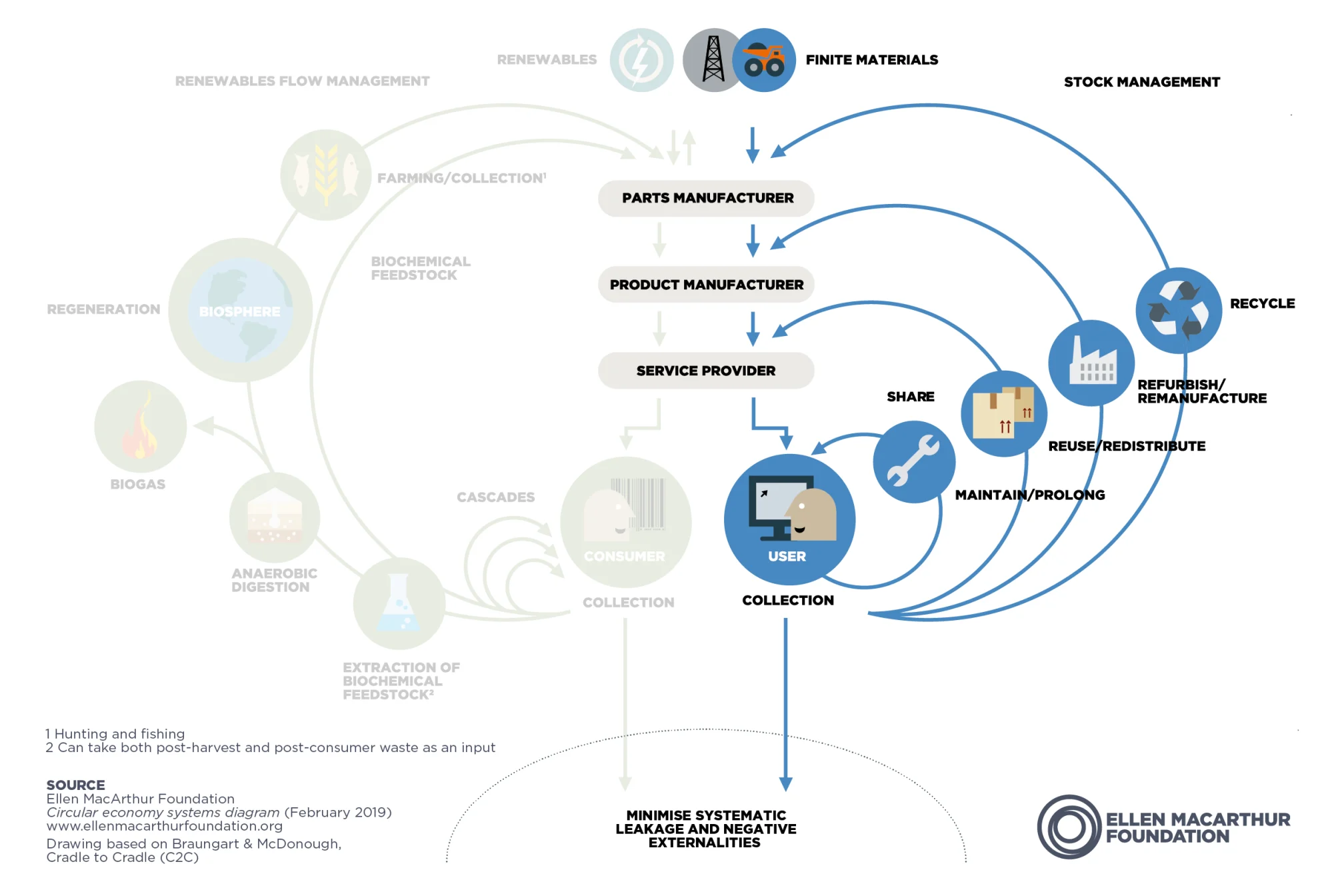

The Butterfly Diagram

In the contemporary landscape, the term "circular economy" has become omnipresent, resonating with the global push towards sustainable practices. However, behind this familiar expression lies a conceptual structure that is not always apparent to everyone. This article aims to delve into the foundational elements of the Butterfly Diagram.

Understanding each facet of the two cycles that compose the framework is not just an academic exercise but a gateway to envisioning our future roles as influential actors in the economy. Each loop of the diagram can serve as inspiration for individuals to contribute meaningfully to sustainable practices. To show how loops can bring innovation and eco-efficient measures at the end of the article there are some business cases that draw from managerial, economic and financial perspectives.

the Biological Cycle

It involves the circulation of products and materials by emphasizing the importance of extending their lifespan through reuse, repair, and recycling. In this stage, waste is minimized, and resources are conserved, forming a closed loop that challenges the traditional linear "take, make, dispose" model.

It is designed for materials capable of biodegradation and safe return to the earth.

Regeneration:

The focus is on building natural capital instead of degrading nature.

Practices include: regenerative agriculture, restorative aquaculture, agroecology, agroforestry, and conservation agriculture.

Business Case: In 2023, Maritaş Denim collaborated with Harran University and Gaziantep University on a project focusing on regenerative cotton production. Their commitment to regenerative farming methods, harmonizing with natural systems, minimizes reliance on virgin inputs, decreases chemical usage, and promotes water and soil conservation.

Farming Practices:

The aim is a sustainable management of farms, forests, and fisheries for positive outcomes.

Goals include: healthy soils, improved biodiversity, better air and water quality, and increased carbon storage.

Business Case: Developed by farmers Colin Seis and Darryl Cluff on the Winona farm in New South Wales, pasture cropping involves direct-drilling winter cereal crops into dormant perennial pasture grasses, creating a biodiverse pasture enriched by livestock during the summer. This approach not only prevents bare fields but also safeguards against erosion, reduces water loss, supports biodiversity, and supplies crucial carbon food to sub-soil microbes.

Composting and Anaerobic Digestion:

Composting = microbial breakdown of organic matter in the presence of oxygen (composting) —> Soil enhancer

Anaerobic digestion = production of biogas and solid residual in the absence of oxygen —> Energy source

Business Case: Established in 2001, Cré advocates for composting and anaerobic digestion, promotes quality-assured products, encourages best practices, and supports proper organic waste management. The organization also backs home composting, research in relevant sectors, and keeps members informed about emerging technologies.

Cascades in the Biological Cycle:

This loop aims at utilizing existing products and materials in the economy. Materials move to outer loops when they can no longer be used, returning to the soil.

Examples include: using food by-products for textiles or designing new food products from waste.

Business Case: Mondi is a global packaging and paper Group close to creating a closed-loop supply chain. The company supplies consumer packaging, advanced films, and components for hygiene products, through the Casecade in the biological cycle of wood.

Extraction of Biochemical Feedstock:

It involves using post-harvest and post-consumer biological materials as feedstock because sequential processes can generate high-value biochemicals, nutraceuticals and bulk biochemicals.

Examples: biorefineries producing low volume but high-value chemical products.

Business Case: CCm's technology utilizes captured carbon dioxide (sourced from industrial power generation to stabilize diverse materials) derived from agricultural and industrial waste streams and transformse it into new fertilizer products with a markedly reduced carbon footprint.

the Technical Cycle

The focus is on the regeneration of natural systems by recognizing the symbiotic relationship between the economy and the environment.

Here, the emphasis is on responsible sourcing, renewable energy, and the restoration of ecosystems, ensuring a harmonious balance between economic growth and environmental preservation.

Sharing:

It is the first step in the technical cycle because it increases product utilization. It encourages collaborative use, reducing underutilization and promoting resource efficiency.

Examples: community tool libraries, shared wardrobes, car-sharing, Airbnb.

Business Case: Rheaply empowers organizations with a re-commerce platform designed for furniture, fixtures, equipment, and building materials. Through a fusion of intelligent inventory management and interconnected nationwide marketplaces, the platform prevents furniture and various resources from ending up in landfills by facilitating their transfer to those in need.

Maintaining:

Techniques for prolonging the life cycle of a product.

Example: car or house maintenance, electronics repair shops, furniture restoration.

Business Case: Clothes Doctor provides convenient clothing repair solutions and educates customers on proper garment care. The company, born out of dissatisfaction with traditional repair services, caters to two main customer groups: those passionate about preserving beloved garments and environmentally conscious individuals seeking to extend clothing lifespans.

Reusing:

The aim is to create a loop in the technical cycle that keeps products in their original form and purpose.

Example: reusable packaging addresses waste, while clothing resale platforms reduce the need for new items.

Business Case: Renault has put up Europe’s first circular economy imprinted factory. Remanufacturing vehicle components such as gear boxes and turbo compressors, increasing recycled plastic content and creating a second life for electric batteries are among the innovative solutions implemented.

Redistributing:

This pocess involves diverting products from their intended market to another customer to prevent waste.

Example: fashion resale platforms, food redistributing networks, technology redistribution programs.

Business Case: Depop offers a platform where individuals connect to buy and sell items, contributing to redristibuting fashion items and promoting second-hand shopping. Moreover, 60% of Depop users base their purchasing decisions on fashion companies' commitments to environmental sustainability, particularly in reducing their fashion footprint.

Refurbishing:

The core process is restoring products' value by repairing or replacing components.

Example: reconditioned industrial machinery, tech refurbishing centers, car remanufacturing facilities.

Business Case: Back Market is an online marketplace that specializes in the refurbishment and resale of electronic devices, including smartphones, tablets, and laptops. Founded in 2014, the company operates with a mission to reduce electronic waste by giving renewed life to used electronics.

Remanufacturing:

It is an intensive process that applies when products can't stay in circulation in their current state. It represents a cost-saving to businesses and customers, ensuring products don't become waste.

Examples: re-engineer products and components to an as-new condition

Business Case: Siemens Remanufacturing focuses on extending the life of medical imaging equipment. Components are upgraded, and the systems undergo thorough testing to meet current standards.

Recycling:

The final step in the technical cycle is reserved for products beyond refurbishment or remanufacture. It is crucial for items not suitable for other steps, like single-use packaging. Despite losing the embedded value, recycling retains the value of the materials, promoting resource circularity.

Transforms products into basic materials and reprocesses them into new materials.

Business Case: Seenons is a tech company offering IT solutions and logistics for circular waste management.

Written by Federica Malizia

Reference List:

Ellen McArthur Foundation (2023) The butterfly diagram: visualising the circular economy. https://www.ellenmacarthurfoundation.org/circular-economy-diagram

Ellen McArthur Foundation (2022b, May 23) The technical cycle of the butterfly diagram. https://www.ellenmacarthurfoundation.org/articles/the-technical-cycle-of-the-butterfly-diagram

Ellen McArthur Foundation (2022c, May 23) The biological cycle of the butterfly diagram. https://www.ellenmacarthurfoundation.org/articles/the-biological-cycle-of-the-butterfly-diagram

https://www.backmarket.com/en-us/about-us

https://news.depop.com/who-we-are/about/

https://www.siemens-healthineers.com/

https://seenons.com/en/

https://www.renaultgroup.com/en/our-company/locations/flins-plant-2/

https://clothes-doctor.com/

https://rheaply.com/#

https://www.ccmtechnologies.co.uk/

https://www.mondigroup.com/sustainability/map2030-framework/circular-driven-solutions/

http://www.cre.ie/web/about/

https://winona.net.au/

https://www.maritasdenim.com/